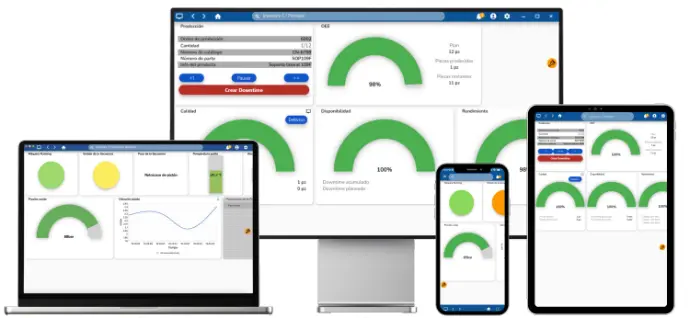

With our software Automata Operations, you can easily manage your industrial operation from your mobile device or computer

It's all you need.

Instantly

Quality

Efficiency

If we don't measure, we don't improve.

Enable better decisions on the production floor based on real efficiency metrics and current status and indicators.

Improve, without loosing control.

Set up standardized processes with controls that reduce waste and rework, mitigate costly and reputational risks, and contribute to your quality warranty.

Time is the most valuable resource.

Frequently asked questions

Answers to some the most common questions

⭐ We offer a software to increase the productivity while ensuring the quality of your products, giving you instant visibility into the status of your plant operations.

🔎 We conduct free diagnostics*, in which we evaluate current operating conditions and propose priority solutions that will impact the business from month one.

+ We also participate in projects to install the sensors and hardware that apply to your operations, if this is a necessary step. If required, we typically carry out these projects with partner companies or with the trusted collaborator you already have, acting as part of the technical architecture team that designs the integral solution and providing close support during the implementation of the hardware project.

+ The other type of project that may be required is to integrate our software with one that you already manage for certain data or functions, such as an ERP or existing databases. If such an integration is required, we participate in the implementation of the project in the same way as with the hardware, taking part in the definition of the technical architecture and providing close support to ensure that the integration of the software is a success.

We have experience collaborating with multidisciplinary teams and provide special visibility on the key pieces of the puzzle so that you always have a clear understanding of what digitalization projects entail and their deliverables 👍

*Travel expenses may apply.

There are two parts: hardware and software.

🔧 The hardware depends on your processes, we can install low-cost sensors to monitor production and/or the condition of machines/equipment if you don't have them. We can also connect to machines to extract production and condition information.

💻 At the software is where you monitor the production. It is also used by any member of your organization for different activities depending on their functions, some examples:

- The operator records production defects and instantly notifies to the maintenance team about problems.

- A production supervisor can use it to monitor which production line is deviating from its target and is at risk of missing the shift target if emerging problems are not addressed.

- The manager can identify trends and prioritize resources to address real areas of opportunity in the operation.

The software can run on any device you have on the production floor, typically computers or tablets. You can download it from app stores, or we can provide the installer

The software is configured with your processes, whether they are machines/equipment or manual workstations, so that the members of your organization can use the software and its functions according to your specific operation.

In general, it depends on your operation and how many production lines or areas of the operation you want to implement the solution.

However, in addition to our exceptional software, we have a methodology and hardware with which we can implement quick wins in about 30 minutes.

An example of quick win is having real-time monitoring of productivity on a critical production line, machine, or workstation. You will have an instant indicator of how production is going, the operator will have a way to report defects and issues, and the supervisor will easily follow up to resolve them..

The quick wins will immerse you in the digitalization of your operations in an agile way, shortening the time to achieve real value.

Once it is clear through quick wins the great benefits, we are sure you will want to enable all of the potential. Your entire plant can be covered in 1 or 2 months depending on the size of your operation, the scope, and the hardware that will need to be installed.

Schedule a meeting with us using any of these links:

We can also schedule the meeting for you or schedule free trials✨, ask for them...

- calling us to +52 81 4162 3134

- writing a message to our WhatsApp

- writing to our email contact@automatasystems.co

- or leaving your contact data through this brief form.

Enabling all of the potential in your organization is just a decision away! ⚡

⚡Recognitions and participations on acceleration programs🚀